- #Stepper motor serial controller .exe#

- #Stepper motor serial controller 32 bit#

- #Stepper motor serial controller full#

- #Stepper motor serial controller code#

- #Stepper motor serial controller download#

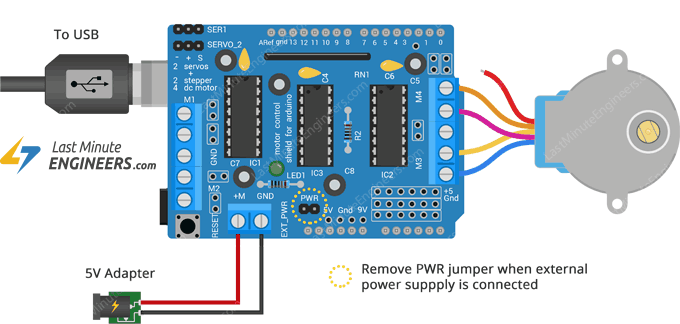

settings and prevSettings are for keeping track of the data sent by the master ESP32 board. maximumSpeed is for safety and defaultSpeed is for movements where steps per second are not specified. That’s why we need to also know the stepsPerRevolution. That maximum amount of volume can be pushed by the crank shaft linked to the stepper motor axle at half a revolution. maxBVMVolume is used to determine the ratio between the received volume setting and this maximum volume possible. stepperParams are of a size of 3 (steps to move, steps per second for inspiration, steps per second for expiration). homeSet, isHoming, isStopping are control variables to discern the current operation the stepper motor is engaged on. It would help you to better picture the project set up.īetween the lines 6 and 9 we assign the pin values. fzz file from here to take a look at the breadboard and schematic views.

#Stepper motor serial controller download#

The fantastic and very well known AccelStepper library is used of course to control our stepper motor.ĭo not forget you can download the Fritzing. We need the Wire library to be able to receive new settings via I2C from the master board ESP32, Arduino Nano being set up as a slave. Importing libraries, assigning values to constants and variables

#Stepper motor serial controller code#

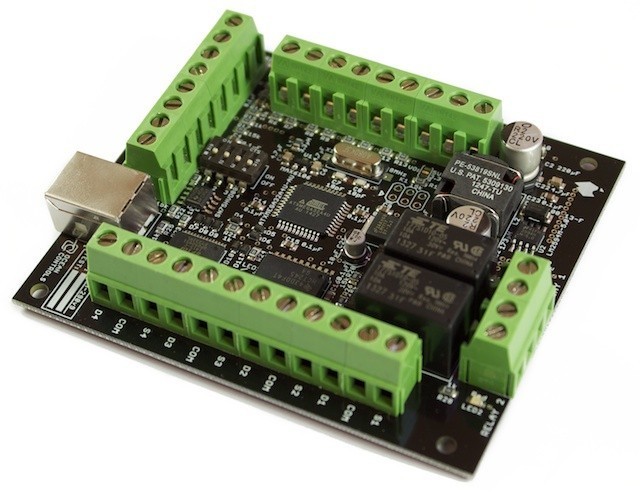

If you prefer to write your Arduino code in let’s say Visual Studio Code fzz file with breadboard and schematic viewsĪccelStepper library created by Mike McCauley and maintaned by Patrick Wasp ( waspinator github account)ĭroneBot Workshop YouTube Channel: Big Stepper Motors with Arduino Importing libraries, assigning values to constants and variables.Analog voltage inputs and auxiliary digital IO.Parameters can be stored in non-volatile EEPROM.Easily connect multiple units by RS-485 for up to 16 axes.USB Virtual serial port or RS-485 input.In our case we will set address to 0x20 and choose.

#Stepper motor serial controller .exe#

exe and in a Driver setup tab select Enable auto run and set Modbus address and configuration. Use USB cable to connect with the PoStep60-256.

#Stepper motor serial controller 32 bit#

Positions are stored internally as signed, 32 bit integers allowing for a range of more than ☒ billion steps Please note these are not G-Code commands and it will not accept G-Code We provide a free Windows example program with Visual Basic source code that allows a sequence of commands to be sent out the serial port.Įxamples of the AMOV 1000 2000 4000 do an absolute move of stepper 1,2 and 3 to positions 1000, 2000 and AMOV 2000 do an absolute move of stepper 1 to position RMOV -400 do a relative move of stepper 2 400 steps POSN 10000 indicate stepper 3 is at position STOP stop all motors connected to the STAT card sends the status of motors 1 to 4 whether they are moving or not and status of limit switches. Any terminal program (Hyperterm, TeraTerm, RealTerm etc.) or programming language capable of sending strings out a serial port can be used to generate the strings for the controller. Controls 4 axes of stepper or servo motors simultaneously USB Virtual serial port or RS-485 input Easily connect multiple units by RS-485 for up to 16 axes.

Motors connected to the 290 are controlled using simple ASCII commands. It uses many of the same simple ASCII commands. The KTA-290 is a major improvement over our KTA-190, featuring more accurate frequency generation, smoother ramping and USB communication. This allows control of up to 16 axes of motors. The card also acts as a USB to RS-485 serial converter, allowing you to multidrop up to 4 interface cards off the RS-485 serial line. Once connected to a computer, the card appears as a virtual serial (COM) port.

#Stepper motor serial controller full#

The step and direction outputs of the card can connect directly to almost any stepper or servo motor driver, including the full range of our Leadshine motor drives. The controller is an upgraded version of our popular KTA-190. Simple commands allow the independent motion of the motors.

Description: The KTA-290 is a USB or RS-485 controller card that generates the pulses to feed to up to four axes of stepper or servo motor drivers.

0 kommentar(er)

0 kommentar(er)